Our History

Qingdao Huichen Logistics Technology Co.,Ltd has focused on modern

storage system equipment for over 20 years in China. as one of

largest professional warehouse storage equipment manufacturer in

north of China,which is focusing on the warehouse

solution,manufacturing and installation.

Our Factory

The company has 2 automatic punching lines, 19 rack-making

production lines,2 large shot blasting machines,4 flame plating

lines, Annual production capacity of 10 million tons.

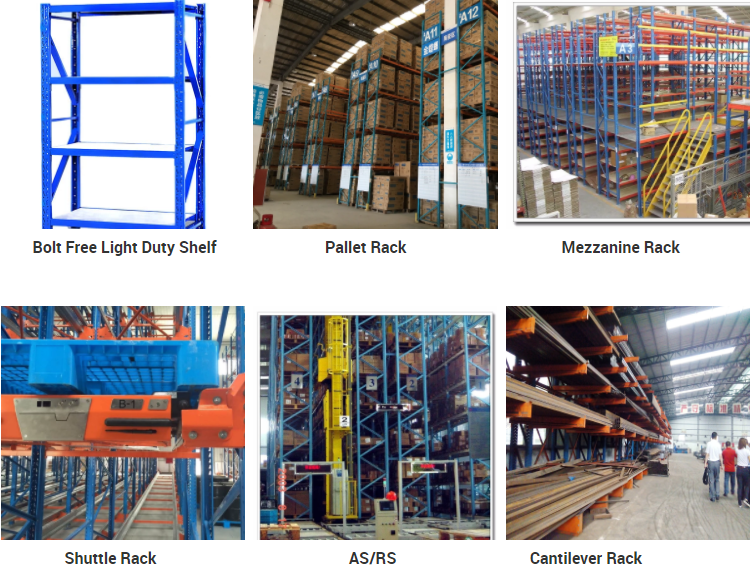

Our Product

Our main products cover :

1. all kinds of industrial racking: radio shuttle racking,

selective racking,automated warehouse,

2. pallet,storage box;

3. section bar;

4. table trolley;

5. materials handling series equipment and so on.

We supply racking and material handling equipment all over the

globe to a wide range of companies worldwide, ranging from large

multinational organizations to small individual companies.

Product Application

Warehouse storage racking for Industry use are widely used in the

following industry, such as:

--- Food,

--- Chemicals,

--- Auto,

--- Pharmaceutical

--- Electric products,etc...